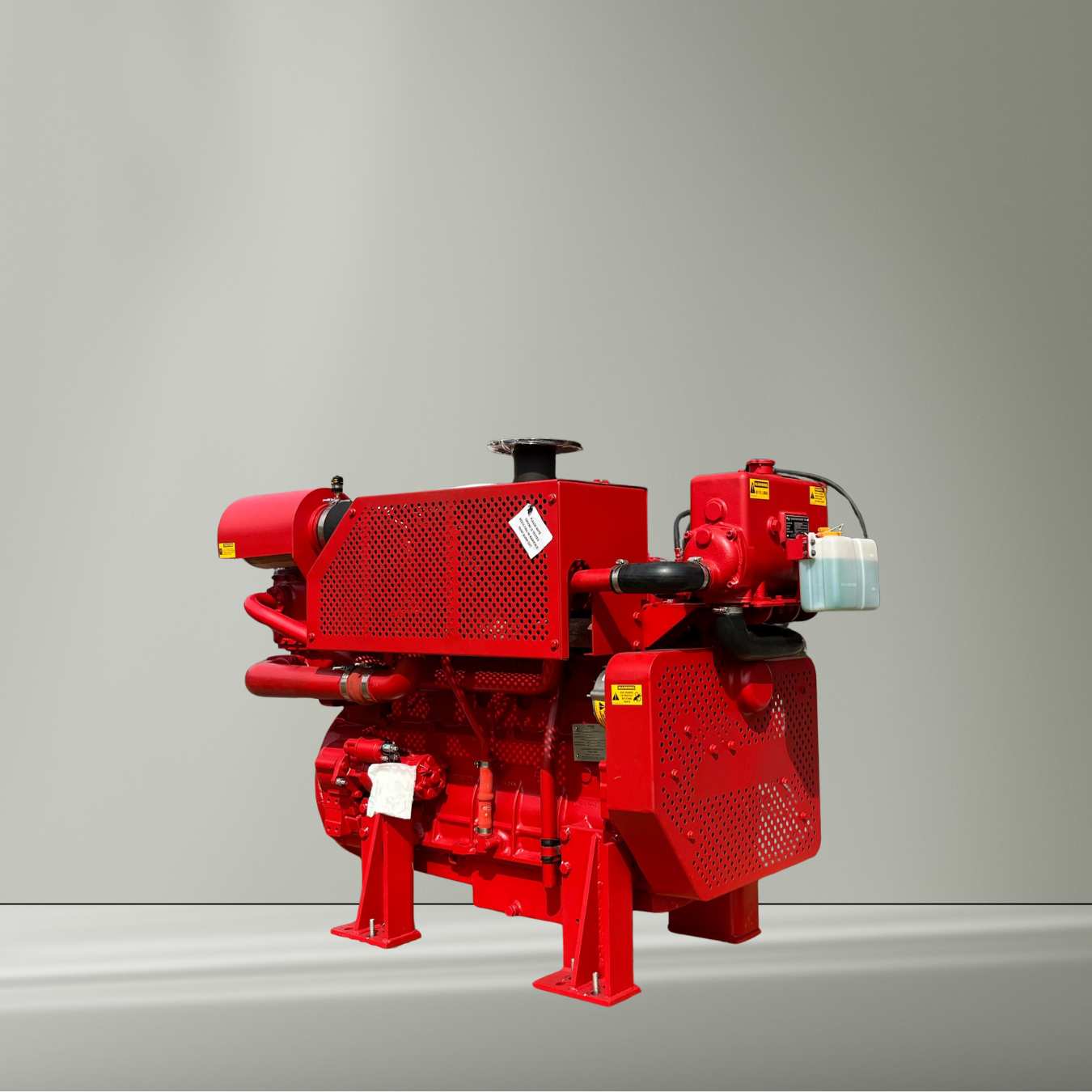

Diesel Engine-Driven Fire Pump Packages: Causes of Excessive Vibration

Diesel engine-driven fire pump packages play a critical role in fire safety systems, particularly in industrial and commercial settings. However, excessive vibration is a recurring issue that can significantly affect system performance and compromise the structural integrity of the equipment. Several key factors contribute to vibration in diesel engines used in fire pump packages, including:

- Misalignment

Misalignment between the diesel engine shaft and the pump shaft is often a primary cause of vibration. This condition may result from improper installation, positional shifts due to prolonged vibration, or damaged coupling components. Misalignment causes rotational imbalance, which can lead to bearing failure, premature wear, and increased dynamic vibration. - Improper Mounting

Improper installation of the engine and pump unit—such as uneven foundations, loose anchor bolts, or inadequate vibration isolation materials—can trigger structural instability. This instability increases the frequency and amplitude of vibration, accelerating mechanical degradation. - Internal Engine Failure

Internal engine issues such as component wear due to poor lubrication, engine block scoring, or crankshaft failure are serious sources of abnormal vibration. These problems are commonly linked to poor maintenance practices, neglected service intervals, or the use of non-compliant lubricants. - Lack of Preventive Maintenance

Failure to implement a structured preventive maintenance program is a frequently overlooked contributor to vibration. Routine tasks—such as checking the lubrication system, recalibrating alignments, re-torquing foundation bolts, and inspecting rotating components—are essential to maintaining operational stability and performance. - Engine Overspeed Protection Failure

The overspeed protection system is designed to shut down the engine when rotational speed exceeds safe operational limits. If this system malfunctions, the engine may operate uncontrollably at excessive speeds, resulting in severe vibration and potential catastrophic internal damage.

Vibration control in diesel engine-driven fire pump packages requires a comprehensive approach that encompasses precise mechanical installation, adherence to preventive maintenance standards, and reliable engine protection systems. Routine evaluation of component alignment, mounting conditions, and internal engine integrity should be integral to inspection procedures. Furthermore, ensuring the proper function of safety systems such as overspeed protection is critical to preventing major failures. By consistently applying these best practices, operational reliability and fire system readiness can be effectively maintained under emergency conditions.